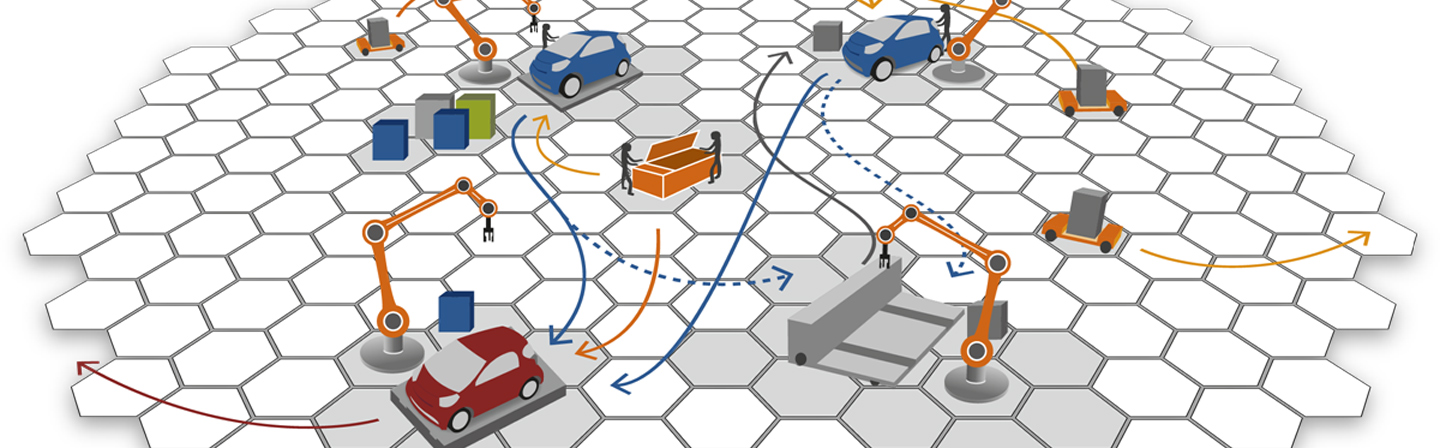

Manufacturing in the future will be individualized, decentralized and self-organizing.

The SMART FACE consortium project

With increasingly shorter product lifecycles and a constantly growing, customer-induced number of product variations, the classic assembly line which traditionally focused on maximum productivity is no longer able to meet the demands of today’s small- and micro-series production.

Present-day production planning tends to be geared towards the classic assembly line and based primarily on the principle of centrality. The possibilities of shifting from a centralized to a self-regulating, decentralized production line are limited, with the flexibility and versatility of resources suffering as a result.

For this reason Smart Face calls for fresh thinking on modern production planning and control methods. In contrast to existing projects Smart Face seeks to develop innovative approaches to the applications of decentralized and autonomous control methodologies and thus create the conditions for the development of a fundamentally new breed of production planning.

Aim

An interdisciplinary research and development project, Smart Face endeavors to develop sustainable concepts and methods to meet the specific demands of micro-series production with regard to operation, scalability, robustness, flexibility and economic efficiency. Its special focus lies in production planning for electric vehicles, with a view to applying the findings to other fields in future.

The core of the research project addresses the principle of the Internet of Things, whereby products throughout the supply chain are clearly identifiable and locatable. So-called cyber-physical systems (CPS) allow for an autonomous exchange of information between objects.

The challenge of the Smart Face project is to combine the CPS approach with existing technologies and production structures in order to create novel and innovative solutions for lean production planning in small- and micro-series manufacturing.

Innovation

The research project is expected to bring us a significant step further towards lean production with adaptable manufacturing structures. Thanks to decentralized, highly flexible material flow units, for example, machines are able to request assembly parts independently and to spread out their workload autonomously. The centralized sequence schedule will become superfluous, bringing multiple advantages with regard to issues such as flexibility, individualization and batch size 1.

Fraunhofer Institute for Material Flow and Logistics

Fraunhofer Institute for Material Flow and Logistics